FORCE FIELD

Parametrically designed installation

Our present era is accurately referred to as the plastic age. Plastics are versatile materials with an amazing range of benefits that make them irreplaceable in the modern world. However, the use of petroleum-based plastics has serious consequences on our planet. We therefore need projects that approach these issues critically.

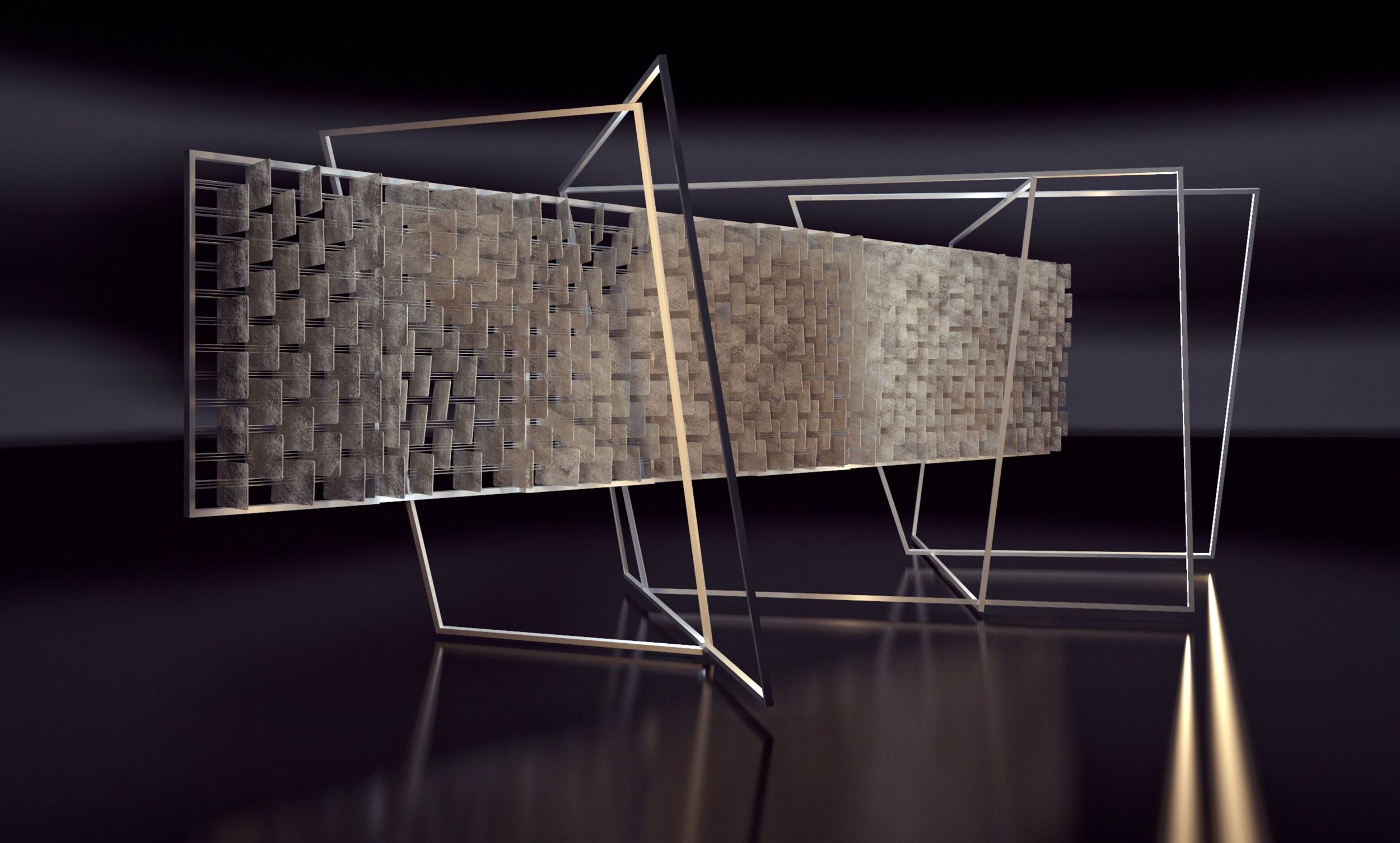

Slovak chemists and designers under the Crafting Plastics! brand developed Nuatan, a bioplastic made only from sustainable, fully-degradable natural ingredients. At the event of one prestigious social event, we created a photo wall which paid tribute to nature using this bioplastic. It was designed by parametric processes and inspired by the flow of natural forces.

- Year: 2019

- Type: Design

- Stage: Design and prototype creation

- Client: Crafting plastics! studio

About the client

Crafting Plastics! is a renowned design studio focused on the research of innovative materials and their practical application. They currently focus on the development and design of Nuatan, a bioplastic made of 100% renewable resources, which does not generate microplastics at the moment of decomposition or contribute to the man-made climate change causes. Nuatan was precisely the material that we presented with our parametric photo wall at the prestigious social event.

Inspiring nature

The phenomena of nature and parametric design have many things in common. We may compare the parametric generation of objects to natural forms that emerge under the influence of several external and internal forces, influence each other and form a comprehensive system. We design them indirectly by defining the forces that create them. Bioplastic, which in a form of panels creates the mass of the installation, has a surface that evokes irregular natural ornaments. This is a result of the production process which involves pressing from granules of different colors and transparencies. Thanks to its degradability, this material is in line with the vision of production with a positive impact.

Parametric design

We did not try to replicate any specific natural form during the designing process. Our way of working requires a thorough understanding of how a particular phenomenon works, so that we can then computationally simulate it and create a novel, comprehensive, yet well-justified solution. With the help of computational tools, we can work and design at the level of simulations of natural systems - we set the forces and influences that create shapes and forms similarly to how they are created in nature. This way we have good control over every small part of a complex design form.

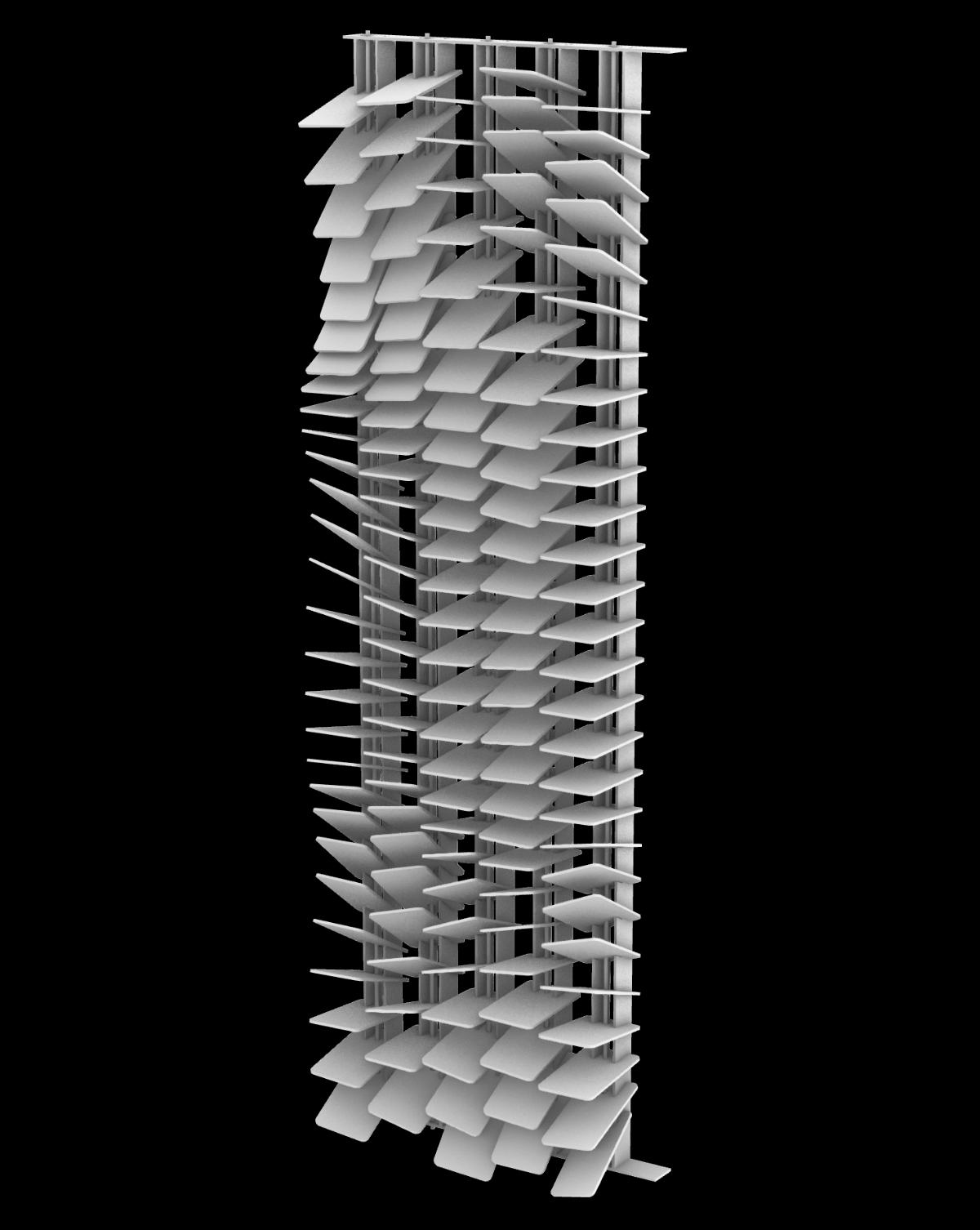

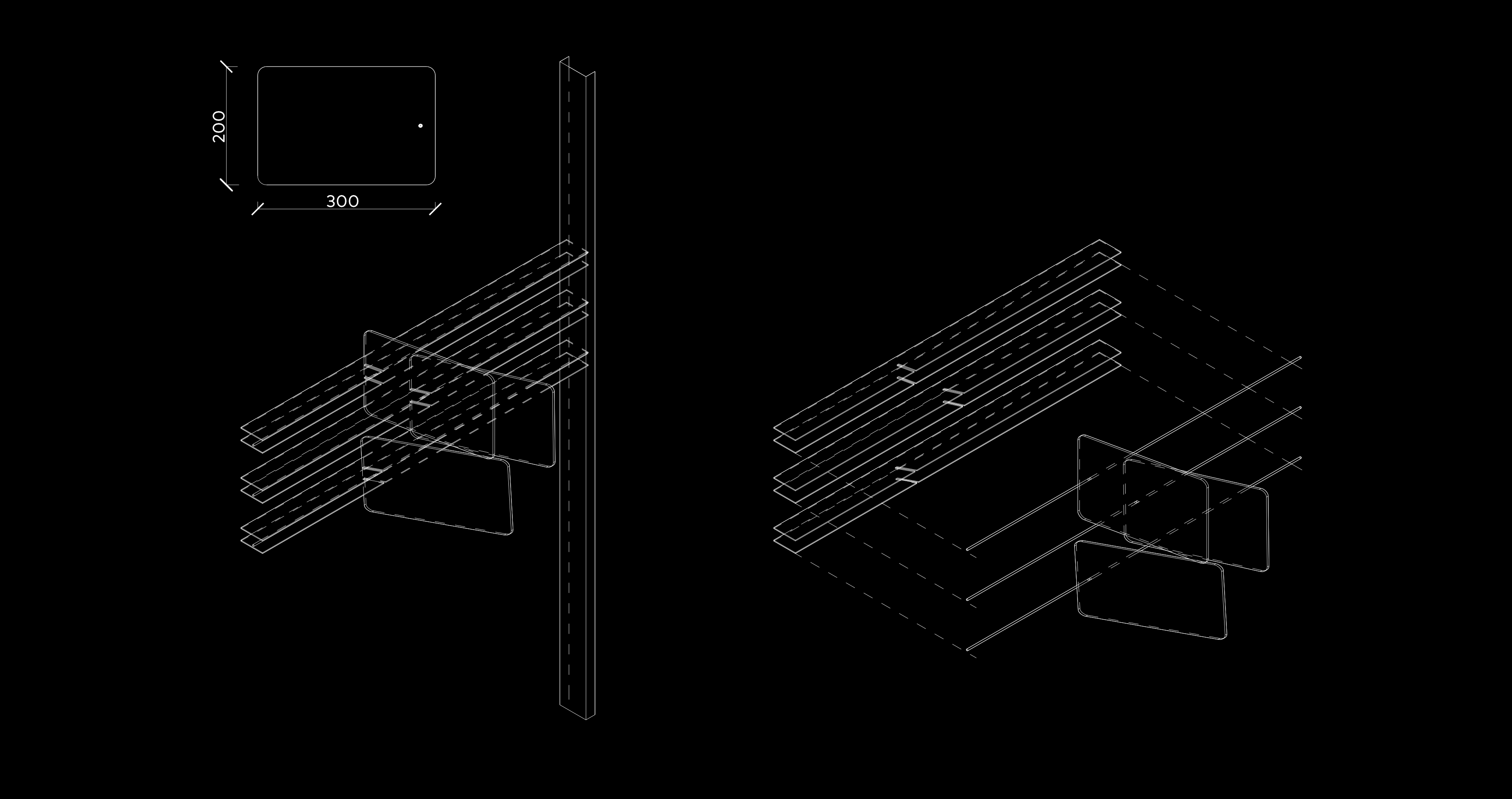

Prototype production

We created a scale model of laser-cut steel plates that helps us verify if all parts fit together properly. Each part of this puzzle is rotated differently, the angle of rotation of each of the plates being defined with mathematical precision. We have absolute control over the design and production process, thanks to which the finished prototype acts dynamically and naturally and is visually intricate and rich. Just like the shapes formed by natural forces.

Each part of the wall is mounted onto the structure at its own specific angle. The angles are precise and mathematically calculated to ensure that the whole result will look natural and dynamic.

Once we understand the phenomenon we are inspired by, it is not an issue for us to define it mathematically – not as the form itself, but as the principle that generates the form. The most interesting moment of a project is for us to transform an interesting principle into an algorithm. We can then automatically and quickly create any number of simulations and designs by simply changing the input parameters.